MICROPHONISM DETECTION AND REMEDIATION

MICROPHONISM DETECTION AND REMEDIATION

By: Don McClatchie

Many dictionaries define Microphonism as “the effect of unwanted modulation that is produced mechanically in an electronic circuit”. Others know it as that annoying noise that a piece of electronic equipment makes when it is bumped or tapped on. The source of the annoying signal is due to the mechanical movement of the components that make up the electronic circuitry. Basically, all electronic components will react to pressure waves (mechanical movement) that changes their electrical properties of resistance and or capacitance and that adds an unwanted signal to the existing signal.

The name itself is derived from a device that is designed to generate sounds from motion, the microphone. There is little said about how to remedy this effect in electronic devices short of saying things like “ coat the components with a wax like or rubber like substance to prevent the component from swinging back and forth (mechanically oscillating) or (shock mount), suspend the device with rubber mounting to prevent the mechanical shock waves from getting to the circuitry and components.

A lesser known fact is that coaxial cable is also Microphonic and if the cable is vibrated mechanically the movement can insert an unwanted spike or oscillation into your signal. As the cable is moved the frequency response of the cable changes due to capacitive changes and if your signal is sensitive to that change the result will be unwanted modulation of the original signal or interference.

Testing for Microphonism is easy to do with audio equipment, just turn up the volume and tap the equipment to see if you can detect any change in the sound. For RF signals you would have to look at the signal with an oscilloscope or similar test equipment to see any changes when you tap on the equipment case.

Not much is said about electronic ways to remedy the problem of Microphonism. Coating all the components with rubbery stuff will bring down the duration of the interfering shock wave but to stop it entirely requires a different approach to remediation. Here is one way to stop the shock wave from getting out of the equipment on the signal.

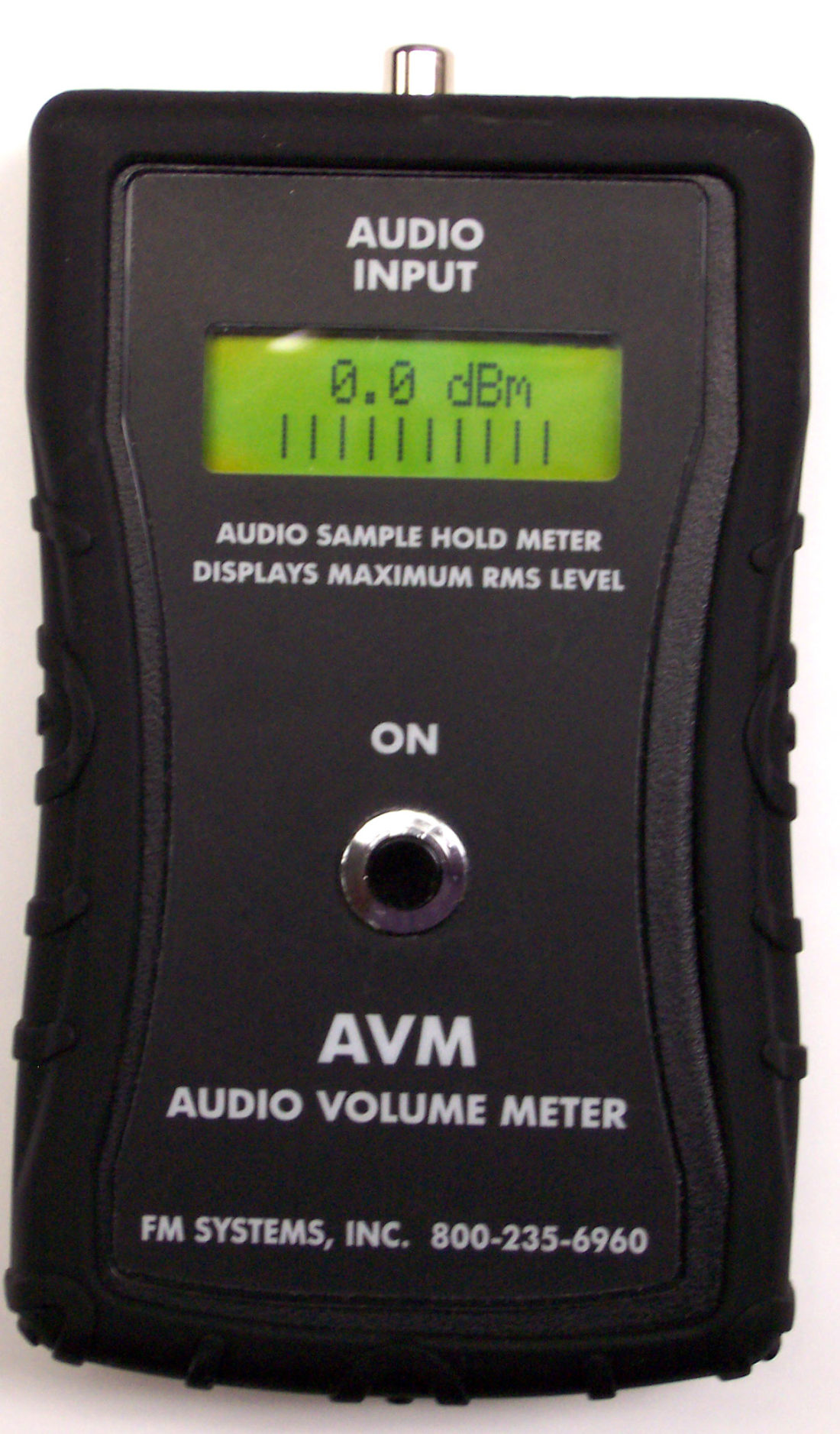

If you have a storage audio dB meter like an AVM you can test for the level of interference from Microphonism by connecting the AVM storage meter to the output of your amplifier with no input signal and then bumping or taping the equipment and reading the dB level of the interfering signal. The storage meter will catch the event and store it for observation. At least then you will know what to expect from the equipment when it is touched.

Let’s say you have an audio amplifier circuit and if you bump it you can clearly hear the thump. If you had two identical amplifier circuits mounted on the same PC board in such a way that they both received the same mechanical movement at the same time, it would easy to arrange for one circuit to carry the audio signal and the other to have no signal input. Both circuits should use the same components and be mechanically built the same. Then if you take both signals that have the shock wave signal on them and put the two inputs into a differential amplifier to cancel the like signals, the output signal would have the shock wave interference removed electronically. The downside is a possible 6 dB increase in the noise signal, but audio devices today have exceptional noise specifications. Sometimes electronic interference problems can be solved by using cancellation techniques.

As an example, I had a customer with a Video signal traveling several hundred feet down an RG-6 cable and they were having an image brake up every few seconds, it was just a regularly occurring blip that would cause flashing on the screen and loss of picture for just a moment repeatedly. As it turned out this cable was at an airport and the airport RADAR was just across the runway rotating around and sweeping energy into the cable. Shielding was in effective at solving the problem, so we developed a small cancellation amplifier as a solution.

The answer was to run a second cable exactly the same length and have it wire tied to the existing cable. This cable was used as an antenna to sample the RADAR signal. It was important for the cable to be the same type used in the installation and to be the exact same length and to go everywhere the original cable went with a termination at the far end. Then both the signal cable and the terminated cable were connected to a deferential amplifier with the signal side attached to the positive input of the amplifier and the terminated cable attached to the negative input side of the amplifier. This caused the interfering sweep signal entering on both cables to be cancelled in the deferential amplifier leaving only the original video signal without the interfering sweep signal.

So, the same thing could be done for a Microphonism problem, physical isolation and encapsulation is a good first approach to solving the problem but if you need to take it further, you can consider cancellation techniques as needed. If your equipment is mobile and subjected to severe vibration during operation, you might consider active cancellation when designing the equipment.