pictures go bad at a certain time of day

This problem is usually caused by a combination of conditions, all of which can be determined and solved by measurement of the luminance video signal and ground loop signal during the picture outage. So if you have ever said “My pictures go bad at a certain time of day” then this article is a good read for you.

The first and most common source is the appearance of a ground loop associated with a particular time of day. That is the ground loop is caused by some equipment being turned on at a particular time of day. We see this mostly at dusk when lights are automatically turned on with timers or photocells. But is can happen at any time of the day basedon the power use in the building.

When the light or other equipment is turned on, the AC current in the building uses the coaxial cable as a ground return and this increases the ground loop problem to a level that can be observed on the monitors. This ground loop can cause the DVR to say no video or just lay the picture on its side, tear it up,or cause it to roll.

The other problem is when the luminance video level comming from the camera is too high and sunlight reflects off of a surface directly into the camera increasing the luminance level beyond what the camera can handle causing Digital overload in the DVR. Of coarse this would happen near dark and in the morning light but it can happen anytime of the day depending on the reflection. To see if this is the problem review the last working recordings of the camera that went out to see if a reflection hits the camera just before the blackout.

CCTV VIDEO GROUND LOOP PROBLEM SOLVING

by: Don McClatchie FM SYSTEMS, INC. Santa Ana, CA.

TEL: 800-235-6960

This article will discuss video ground loop problems in CCTV installations. The cause and how it effects picture quality with solutions to eliminate the problem.

When Video Ground Loop problems or 60 cycle Bars occur, they are easy to see on a video monitor. They look like a horizontal band or bar across the video monitor that slowly moves up the video screen. These bars can be barely noticeable, or can be so bad that the video monitor loses lock and breaks up the picture. If the video camera is Line-Locked to the 60 cycle main power, the bars may stand still in the picture, but they still obscure picture definition and create customer complaints.

The source of the 60 cycle bar originates from the power industries use of local grounds to balance their power grid. Everywhere 60 cycle power is used, a local ground is attached to the power grid to return all unbalanced current flow to ground. As an example, you will notice that every main power breaker box will have a ground wire or conduit going to a ground rod or similar device connected to an earth ground. Every correctly installed power outlet will have a connection to this ground.

Not all grounds are created equal. In fact the earth ground in one building is most likely to have a different voltage potential relative to any other building, even grounds inside the same building will have different voltages between them, based on the uneven current flow of the power load.

Here is how the 60 cycle bar gets into your video picture. If you connect a coaxial cable to a monitor or other equipment that plugs into the 60 cycle main power and the other end of the coaxial cable becomes grounded locally for any reason a Ground Loop is created. Any difference in the 60 cycle voltage between these two ground points will create a current flow in the shield of the coax that induces the 60 cycle AC voltage into your video signal.

It is easy to measure these differential voltages, simply disconnect the video cables at the monitor point and using your voltmeter on AC volts, measure between any two shields of the incoming video cables, you will be amazed at the difference.

The solution is to never connect both ends of a video cable to local grounds. Any cable can be grounded at one end without inducing the ground loop current. When you run coax cable from one building to another, it is acceptable to install through connection points, but do not allow the shields to come into contact with one another or the local ground. A coaxial connector laying in a cable tray or conduit box can accidentally contact ground, don’t let this happen. Use tape on the connector to prevent accidental grounding. Also try not to attach the camera to any structure that is likely to be grounded. Remember that the camera is already grounded at the opposite end of the coaxial cable by the monitor equipment.

At the monitor station you may have many pieces of equipment connected together, like a (Quad, Tape Recorder, Monitor) all of which plug into the main 60 cycle power. This will not present a problem if you plug all of the equipment into the same power line at the monitor point. Making sure that all the equipment share the same ground point at the monitor station. Also try to keep the video cables between equipment, (the service loops) as short as possible.

If you already have an installation that has 60 cycle bars, there are some steps you can take to solve the problem. If coaxial cable shields are connected together anywhere in the system, separate them if possible. Similarly remove all but one ground connection on each coaxial cable if possible. The ground is usually at the monitor end of the coaxial cable because the monitor equipment plugs into the 60 cycle main power supply which is grounded.

Sometimes a ground loop problem can be reduced by reversing the AC plug on the power transformer used to power the camera, or reverse the 24 VAC power connection to the camera. This technique will not work on DC powered cameras.

If the problem still persists, video isolation transformers can be installed at one end of the coaxial cable to block the shield current flow and eliminate the 60 cycle bars.

These transformers must be installed at the coaxial cable that is originating the 60 cycle bar problem. Isolation transformers only work when they can block the current flow in the shield. Once 60 cycle bars become part of the video signal, no economical down stream solution will remove the bars. Use a portable monitor to find the origin of the ground loop problem, start at the camera and move down the coaxial cable until you see the bars appear on the portable monitor. This then is the coaxial cable with the current in the shield. Clear the ground connection or install an isolation transformer at this point.

The type of AC power transformers you use to power your cameras can contribute to Ground Loop problems. A ground can be introduced to your camera “Capacitively” through the power transformer windings depending on the type and construction technique used to build the AC transformer. Some transformers are built by winding a primary (the 110 VAC side) on a metal core, then simply winding the secondary coil (24VAC) directly over the primary coil. This puts the primary and the secondary in direct capacitive contact. This type can cause Ground Loop problems.

Other manufacturers build their AC transformers with a split bobbin. That is each winding is separately mounted on the metal core. The separation of primary and secondary coils are greatly increased, reducing the capacitive coupling and removing the unwanted second ground in your system. This type of transformer usually does not cost any more, and may prevent the 60 cycle ground loop from occurring. It would help if you determine which transformers are built to minimize capacitive coupling between windings and purchase that type only.

With an understanding of Ground Loop problems and the use of good single ended grounding techniques, you should be able to keep the 60 cycle bars out of your CCTV installations.

NEW TECHNOLOGY:

The new digital revolution has brought us many new and exciting products for the CCTV industry. The DIGITAL VIDEO RECORDER or (DVR) may be one of the most important upgrades that can be made to any CCTV system. The DVR takes a camera video signal and converts it to a digital bit stream and saves it on a computer hard drive. It can then be played back with remarkable fidelity. This new technology brings with it a new set of problems and solutions. This article will discuss some of the problems and solutions for DVR installations. To understand the problem we must look at the standards.

STANDARDS:

A video standard was developed by the Institute of Radio Engineers so that all manufactured video equipment would be compatible. The unit of measure for this standard is the I.R.E. Unit. One I.R.E. unit is equal to .007142 Volts peak to peak. A Black and White (B/W) video signal is 140 I.R.E. units equal to 1 Volt peak to peak. A color video signal has three vital standard measurements the SYNC = 40 I.R.E. units, the WHITE = 100 I.R.E. units, and the COLORBURST = 40 I.R.E. units. Both the B/W and Color signal measure a total of 140 I.R.E. units, but unlike the B/W signal the Color signal measures 1.142857 Volts peak to peak. The additional 0.142857 Volts peak to peak is caused by the color information called “CHROMA” in the video picture. It is a common misunderstanding that all video is 1 Volt peak to peak. Only a B/W video signal is 1 Volt peak to peak, a Color signal is 1.142857 Volts peak to peak. Now how does all this relate to the DVR problem?

THE PROBLEM:

When properly installed the DVR does not output a video picture, displays a “NO VIDEO” image or has a blank blue video screen. Yet if the video input signal is connected to a monitor it displays a video picture. At first you might think that the DVR is defective, that is very unlikely. It is more likely to be a video level standards problem.

HEADROOM IN THE DVR:

Most DVR’s are designed to accept a video signal of 1 Volt peak to peak with some extra range known as “headroom”. This headroom allows the video signal to exceed the 1 Volt peak to peak by some percentage. Usually 20% over the 1 Volt peak to peak video level. That makes it possible for the equipment to accept a video signal of up to 1.2 Volts peak to peak. The standard Color signal measures 1.142857 Volts peak to peak so this amount of headroom should be adequate. The amount of headroom varies from one manufacturer to another, so you may discover one brand works better than another under certain circumstances, but the problem does not necessarily lie with the DVR.

THE REAL PROBLEM: One of the most over looked problems in CCTV installation is the output level adjustment of the camera. The standard for camera output is SYNC = 40 I.R.E. units, WHITE = 100 I.R.E. units, and the COLORBURST = 40 I.R.E. units. However some camera manufacturers have “fudged” the standards some what. We find that WHITE levels in auto iris and auto shutter control systems to be padded up to 120 I.R.E. units (1.285714 Volts peak to peak). That is 20% above the standard maximum level established by the Institute of Radio Engineers.

When a camera’s WHITE level is set anywhere above 100 I.R.E. units the video signal can exceed the maximum headroom allowed by the DVR and the system will go into digital overload resulting in the failure of the DVR to record a video signal. When a monitor is attached to the video signal the video can be viewed because a video monitor is not sensitive to overload. This would lead you to believe that the DVR is non-functional, when actually the camera level is not set correctly.

SOLUTION:

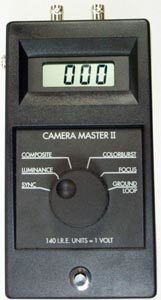

To avoid DVR problems at installation and subsequent service calls the camera’s in the system must be adjusted to the proper standard levels so that the video will not overload the DVR. It is recommended that a Camera Master or waveform monitor be obtained to set the camera’s level accurately. If the type of camera you are using will not allow the WHITE level to be set to 100 I.R.E. and you have already purchased the camera’s, then you can insert a video correction amplifier like the GB-60 and adjust the gain below unity ( a loss of signal) to solve the problem. The Camera Master CM-2 and the Ground Loop Blocker Amplifier GB-60 can be purchased at FM SYSTEMS, INC.

Proper setting of the video levels will correct the problem and an understanding of what causes the problem will help you to solve other level related problems with digital equipment in the future.

If you would like more information regarding this or other CCTV related problems call FM SYSTEMS, INC. CCTV HELP LINE

at: 800-235-6960.