BNC CONNECTORS, THE INSIDE TRUTH

By: Don McClatchie

Not all BNC “Bayonet neill Concelman” that are manufactured for the CCTV video industry are created equal. To get the most out of your CCTV installation and to produce the best video images possible you should consider the brand and the manufacturer’s construction technique very carefully. Cost is not always what determines a good BNC connector from a poor one and knowing what to look for when buying connectors is prudent. It is best to be skeptical of low cost connectors until you check them out. Find out what to look for in a BNC connector.

There are several accepted ways to manufacture a BNC connector in use today. Most of the parts are made from solid brass materials but some parts are cast and machined. The difference is mostly cosmetic and is not a significant problem. However the physical design of thecenter conductoris critical to the overall performance of the connector.

All BNC connectors must meet a strict machining tolerance when it comes to the mating surfaces. That is the part of the connector that comes into physical contact with its mating connector. However the design for attaching the connecter to the cable is left to the manufacturer’s choosing. In this area there are two basic designs used on most of the connectors in the market.

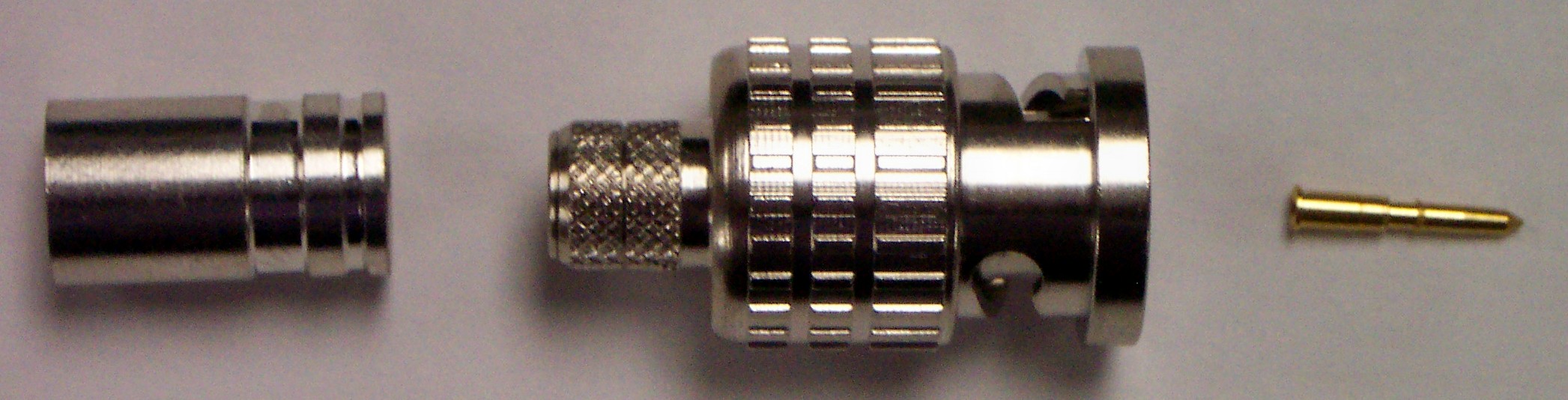

The best design type requires the installer to crimp or solder the center pin in to place on the cable, and then insert the cable with attached pin into the connector body. After that the shield braid is crimped onto the fitting with a ring. Notice the gold plated brass center pin, it crimps or is soldered to the center wire of the coaxial cable, soldering is better but a lot more trouble to do. This design offers the best in low frequency and high frequency response of the coaxial cable and of course will deliver the best video picture. It also has the least change in the characteristic impedance of the signal path and reduces reflections in the video that show up as ghosting in the picture. Also wiggling of the cable does not result in variable loss at the cable connection.

Sometimes the manufacturer will choose a design that is easy to produce and much lower cost per unit to build but this type of design can cause problems with the signal. If you use a connector that has a small hole on the cable side of the connector that is made to insert the center wire of the coaxial cable, your connector may be contributing to reduced picture quality.

This type of BNC connector is less trouble to install but can cause poor picture quality at the time of installation and further trouble over the life of the connector. It can become intermittent over time resulting in substandard video images and signal failure.

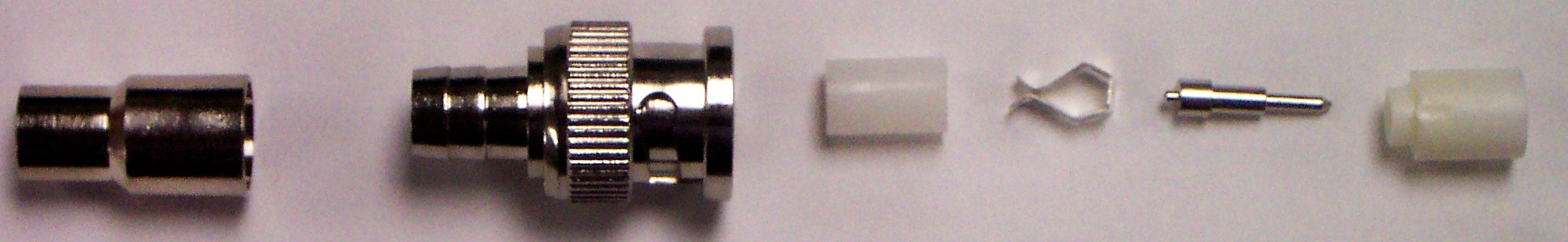

As an example take a look at the expanded view of just such a connector. Notice the turned center pin second from the right and the third from the right stamped wire clip. The wire clip and the center pin of the connector are not physically connected. They are separate parts, one a stamped part made of a spring tempered beryllium/copper then plated “wire clip” and the other is a solid turned part. These parts must convey the signal from one to the other by mechanical pressure exerted by the assembly. This probably works for DC and some low frequencies but at the higher frequencies of video responsible for the definition of the picture this approach should be avoided. The characteristic impedance of the signal flow through the connector will be affected by this type of mechanical change and the result willcause reflections that canproduce ghosting and high frequency loss affecting picture sharpness. Not to mention the variable contact resistance caused by random flexing of the coaxial cable connection that generates internal pressures on the junction between the center pin and the stamped wire clip that affect the signal level when you wiggle the cable at the connector. This problem will cause as much as 1 dB of loss and can even cause intermittent signal delivery with mechanical movement of the cable.

Next look at the center wire clip made from a stamped piece of metal. The center wire of the coaxial cable fits through the connector body and is inserted in between the two arms of the wire clip. The spring tension of this piece maintains two point contacts on the center coax wire. I have also seen connectors that have a groove on each contact to increase the contact area. This contact is continually rubbed clean of corrosion because the center conductor of the cable continually moves with respect to the outer shield. The movement of the center conductor occurs when the cable heats up, and cools down with normal temperature changes. The coefficient of expansion is different for the center conductor verses the shield of the cable and that difference keeps the center conductor moving back and forth slowly to keep the contact area clean. However the contact points are small and can cause low frequency problems in the video signal. This will cause the low frequency part of the video image to sage or tilt affecting the picture quality. On long cable runs the low frequency effect may not be noticeable on the monitor.

The points of contact stay clean if the cable is not disturbed. However if enough time goes by and you touch the cable at the connector you could inadvertently move the point of contact to a place on the center wire that has corrosion and incur greater loss as a result of the change. All of these problems can be avoided by using only the crimp-on or solder on center pin type of BNC connector.

If you have any doubts about the manufacturing type of BNC connectors you are using in your installations, simply have a look at it, take it apart. Look for solid connections through out its design and uniform diameters of both the center conductor and the insulating material. Find the part number and look up the frequency response and reflectivity specifications of the connector if you can find them.

A better understanding of the physical properties of the connectors you use in your installations will improve the end product and help with your understanding of installation problems to speed their resolution. Remember one truck roll to fix a bad connector would buy a huge number of good connectors. Take a good look at your connectors and watch out for the cheap ones. Sometimes cheap doesn’t pay.